- Model U-1641 is 250 mm wide. It is a 4-, 6- or 8-pen recorder with intelligent functions.

A digital servo system has been adopted in moving parts. Potentiometers nor drive wires are not used. There is no need for replacement during a periodical check.

Moreover, Model U-1641 comes standard with a 5-inch indicator. All channels can be checked at the same time. Settings for measuring conditions can also be made easily.

A “16TCV1” standard input unit as 1 unit responds to 2 channels. It becomes possible to switch between a DC voltage and a temperature (thermocouple) within the same amplifier. Measurements can be made of voltages and temperatures.

Features

-

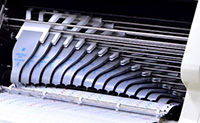

Identically shaped large cartridge pens.

With a recording length of 5km, recordings up to two times the length of our company’s conventional products are possible.Also, because the pen have identical shapes, recording can be done in your favorite color. -

Automatic pen cap system.

When the power supply or measurement are turned OFF, the pens are automatically capped to prevent the tip of the pens from drying. This eliminates the troublesome need to place caps when recordings are not being made. -

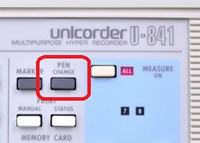

Simple pen replacement.

By pressing the PEN CHANGE switch on the control panel, the pens can be esasily and quickly replaced. -

Sliding control panel.

By manually sliding the control panel upwards, confirmation of pen operation, pen replacements and recorder paper replacements can be easily done.

-

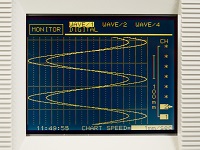

Display

This display can display analog waveforms, digital value and various settings as well as monitor all channels simultaneously.

Further, waveform confirmations can also be displayed in the screen without recording. -

Also comes with an external remote control function.

Operations such as chart drive feed, measure ON/OFF and manual printingcan be controlled externally. Futher, parallel operation is possible using a synchronous output. -

IC memory card included.

Setting conditions can be saved in eight varieties as well as be easily called and setup.

U-841 Specs

| Model |

U-841-4P (4channel) U-841-6P (6channel) U-841-8P (8channel) |

|---|---|

| External dimensions |

438(W)×255(H)×420(D)mm (Projection things are not included.) |

| Mass | 4P Approx.16.5kg / 6P Approx.18kg / 8P Approx.19.5kg |

| Use environment |

|

| Power supply | AC90 to 265V / DC9 to 16V (Option) |

| Operation method |

Automatic balancing system (digital servo system) |

| Effective recording width | 250mm |

| Type or input unit | Plug-in type (2 channels for 1 unit) |

| Reference point |

Right end of chart paper (Left end is also possible by changing the setting.) |

| Pen interval | 4mm |

| Pen speed | Approx. 1600mm/s |

| Chart speed | 10 to 2400mm/min, /h Set in 1mm increments |

| Accuracy | ±0.25% of measurement accuracy and effective recording width including linearity and dead band. |

| Synchronizer | ON, OFF 20 data/mm |

| Measurement ON/OFF | Each channel independent |

| Resolution of time axis | 0.05mm |

| Sampling speed | Max. 4ms |

| Rapid chart drive | 2400mm/min (Reverse rotation is not allowed.) |

| Accuracy for chart drive | ±0.1% when a recording length is 1m over. |

| Chart end detection | Provided. Pens are up and chart drive ends. |

| Swing-out protection | Signal limiter |

| Paper winding-up | Equipped (option) |

| Superimposed marker | Operates by operation switch and external remote controller. (Link with ON/OFF of synchronizer.) |

| Auto pen cap | Pen is automatically stored at the specified position when power is OFF, measurement is OFF and paper ends. |

| Display | 5″ EL display, 320 x 256 dots |

| Display mode |

(1) Range display Simultaneous display for all channels (2) Digital measurement value display (3) Wave (4) AUX (optional screen) |

| Scaling | Range: -10000 to +10000 Decimal point and unit are set arbitrarily |

| Withstand voltage |

Between power supply and chassis (GND) : 1500VAC, 1 minute Between analog input and chassis (GND) : 500VAC, 1 minute Between each an analog input : 500VAC, 1 minute |

| Insulation resistance |

Between power supply and chassis (GND) : 100MΩ or more at 500VDC Between I/O control and chassis (GND) : 20MΩ or more at 250VDC Between analog input and chassis (GND) : 100MΩ or more at 500VDC |

| Power consumption(TYP.) |

4pen At balanced 140W / Max. 250W 6pen At balanced 145W / Max. 250W 8pen At balanced 150W / Max. 250W |

| Recording paper | Roll Recording paper No.2501P50(20m), No.25020P50(50m) |

| Pen | NDL Series All 16 colors |

Input unit 16TCV1

| Compatible machines | U-1641/U-841 | |

|---|---|---|

| Input format | Unbalanced,Floating | |

| Input resistance | 1MΩ fixed | |

| Signal source resistance | Less than 1kΩ | |

| Voltage measuring range | 100φV to 100V | |

| Measurement range |

|

|

| Measurement accuracy | ±(0.05%(rdg)+0.03%(range)+1φV) | |

| Temperature measurement accuracy |

±(0.05%(rdg)+0.5℃) J,K,E,T ±(0.05%(rdg)+1℃) S,R,B |

|

| Temperature characteristics |

|

|

| Noise rejection |

CMRR:AC(50/60Hz) More than 150dB NMRR:AC(50/60Hz) More than 50dB |

|

| Zero point movement range | 0 to ±200%, 0.1% increment | |

| A / D converter |

Resolution: 16bit Sampling period: 4ms |

Option

Interface unit

This interface is used to connect the U-1641 or U-841 to the host computer and input and output settings and measured values.

Model : 16INF2 RS-232C Interface unit

Model : 16INF3 GP-IB Interface unit

Model : 16INF2 RS-232C Interface unit

Model : 16INF3 GP-IB Interface unit

CF card unit

It is a memory unit that records analog data using a CF card.

Model : 16MEM1

Recording paper take-up device

| Model | 16TAK1 |

|---|---|

| Compliance recording paper | Roll recording paper [No.25020P50(50m),No.2501P50(20m)] |

| Operation | Single drive (It does not interlock with the recording paper feed mechanism of the main unit.) |

| Mass | Approx.300g |

| Accessories |

Recording paper winding bobbin 1 Recording paper holder Left and right each 1 |

Cart for recorder

Cart for recorder with drawer

Mode : CAR-1

Mode : CAR-1

Application example

Application example of U-841

- Recording of output waveforms from analyzers.

- Recording of output waveforms from various testers.

- Various experiments at universities, research laboratories, and enterprises.

- Recording of exhaust-gas analyses and fuel economy at automakers.

Example

Paints manufacturers record temperature data as quality control data during curing.Moreover, like paints makers, various manufacturers record and store quality data during product shipment.

One of the reasons for which quality data is recorded and stored by recorders is that a recorder records temperature and voltage signals as waveforms as they are; this makes it difficult to conduct the falsification of data, which recently becomes a problem in various industries, so that the reliability of quality data is enhanced.